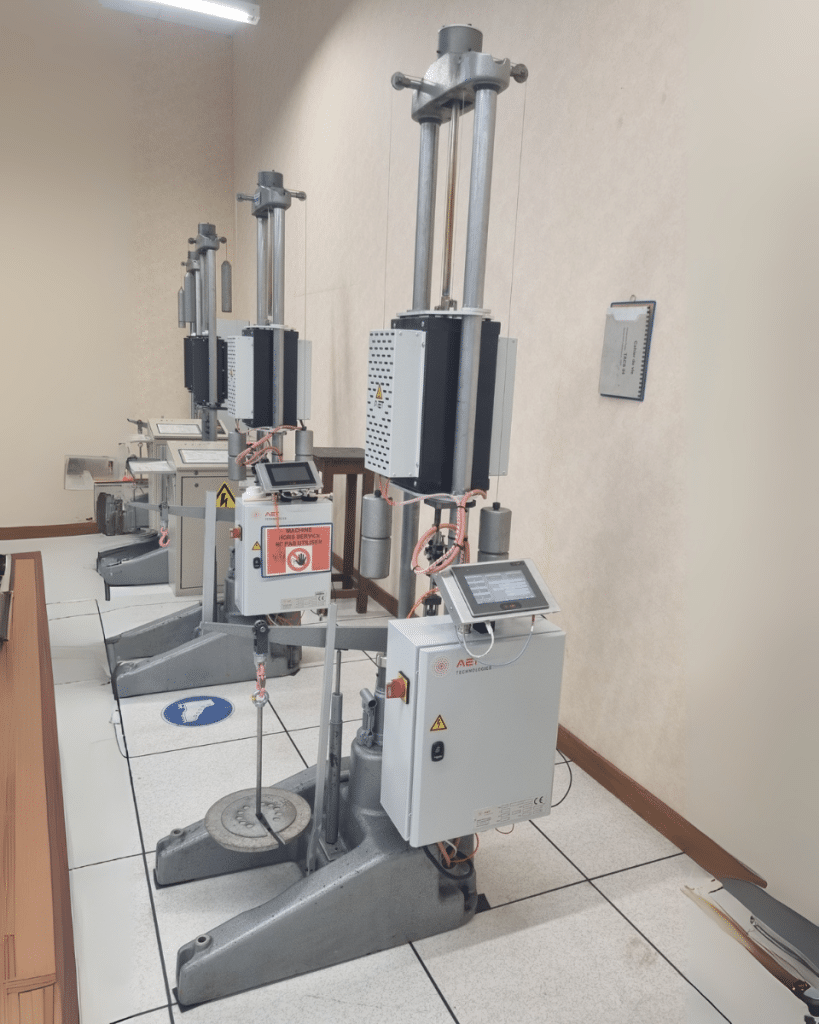

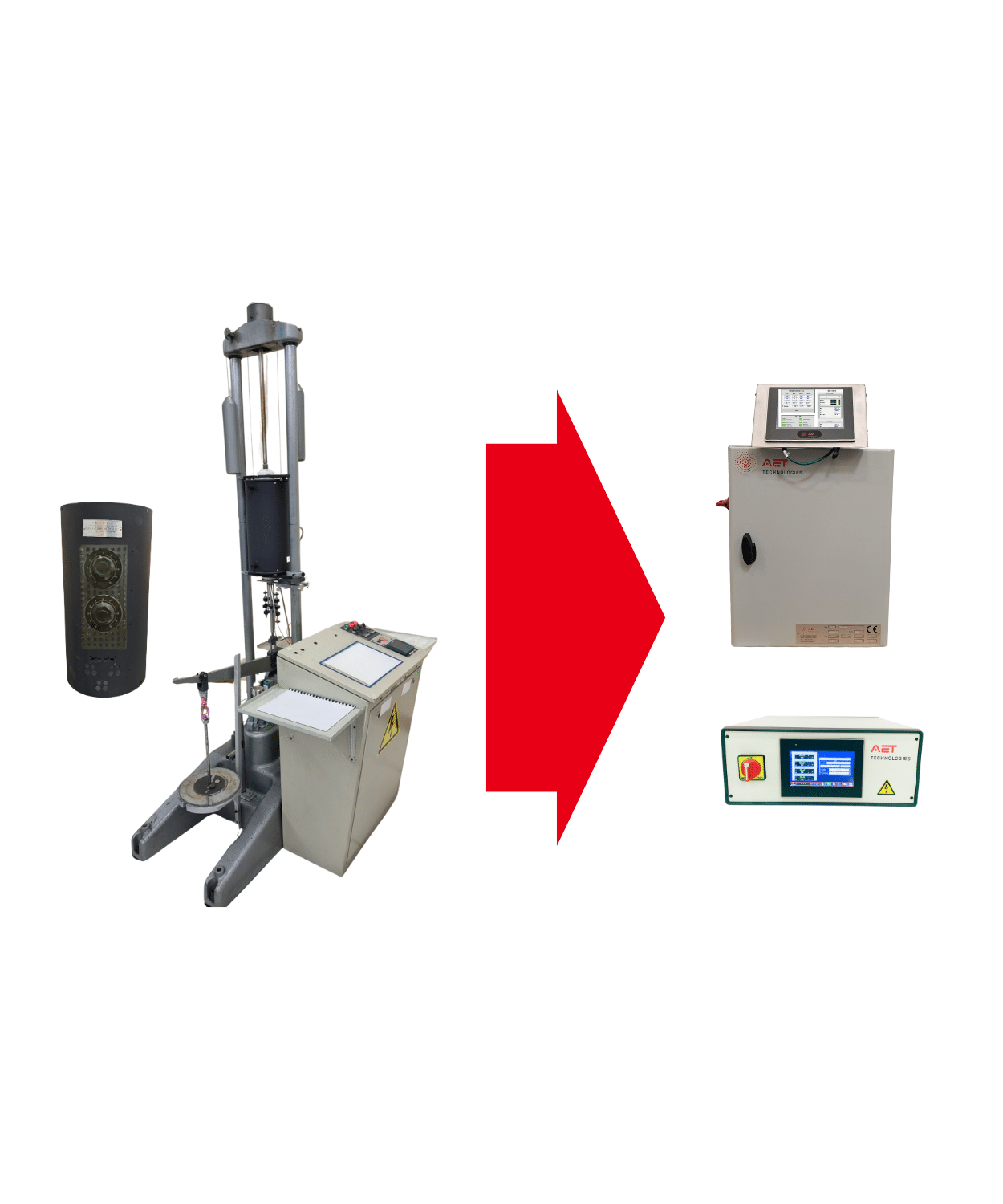

AET Technologies supports its customers in modernising their creep testing equipment through a complete range of retrofit solutions. These interventions, designed and carried out in France, restore full performance and reliability to your installations, regardless of the original manufacturer, by integrating the latest innovations from our expertise in high-temperature mechanical testing.

Our solutions cover both thermal optimisation (temperature increase, heating homogeneity) and the upgrade of control, measurement, or supervision systems. They are adapted to machines and furnaces from different generations to ensure long-term use, compliance with current standards, and alignment with international regulations. Thanks to these upgrades, your equipment retains its full value while meeting the increasingly stringent requirements of research and industry.

Thanks to the use of new geometry heating elements, our continuous 1300 °C model exceeds the current 1100 °C continuous operation limit under air.

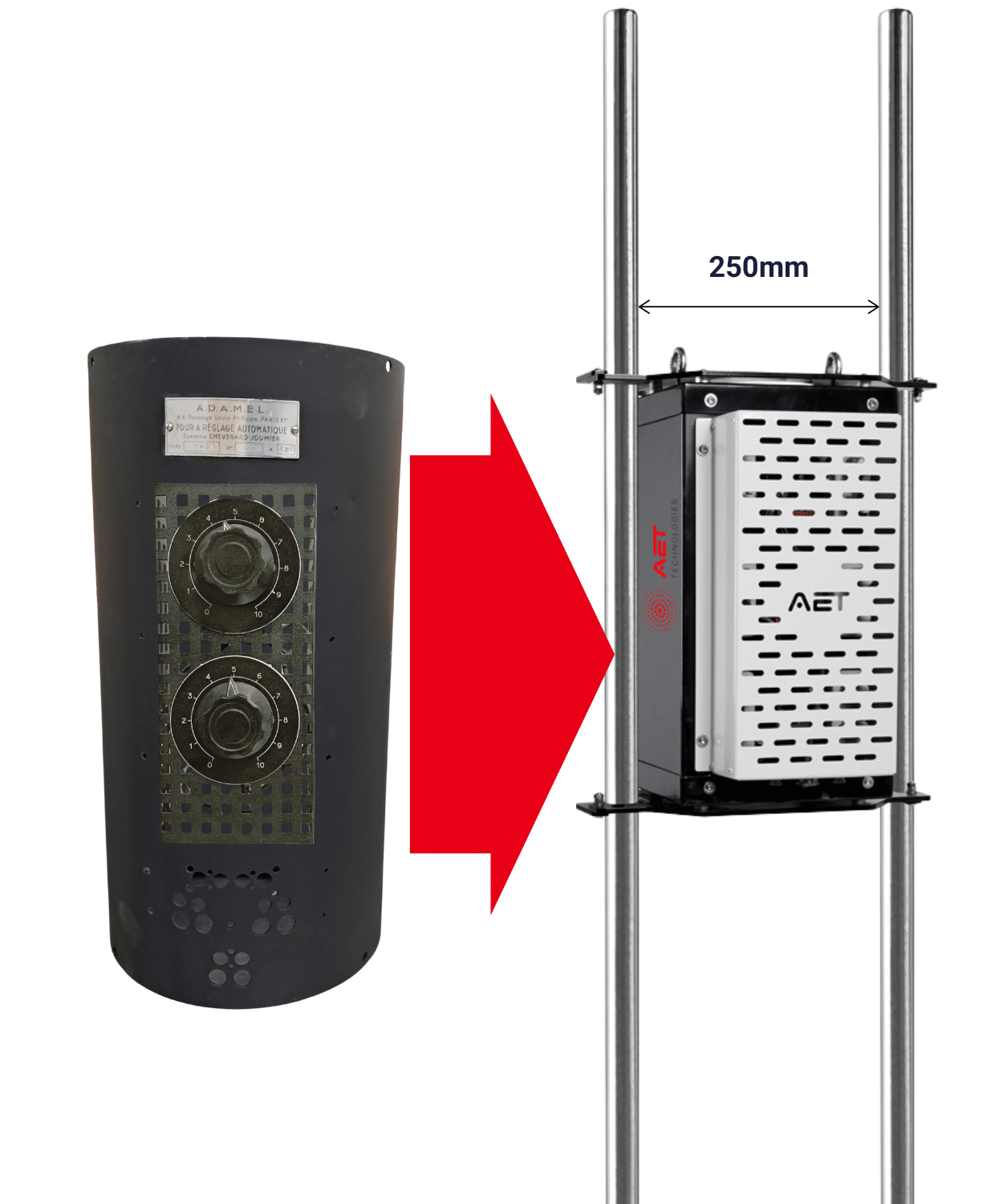

Lanthanum chromite technology enables operation up to 1750°C. Depending on the furnace geometry and available column spacing, we may need to limit its use at certain temperatures (e.g. 1300°C continuous operation for Adamel-type creep furnaces with 250 mm column spacing).In addition to this temperature increase, our heating elements can be individually replaced without dismantling the load column, ensuring fast corrective maintenance, reduced downtime, and continuity of your tests.

This solution is fully compatible with Adamel creep testing machines or any other brand with a minimum column spacing of 250 mm. Its three independent heating zones allow precise thermal control of the furnace or specimen, ensuring excellent temperature homogeneity.

Upgrading a single-zone creep furnace to a multi-zone version (three heating zones) represents a major technical improvement, particularly in terms of thermal control and heating uniformity.

To ensure reliable, repeatable results and an improved user experience, we integrate cascade control. This control mode includes two regulation loops: a master loop and a slave loop. The master loop regulates the specimen temperature, while the slave loop controls the heating elements. In a multi-zone creep furnace (three heating zones), the central slave loop transmits an adjusted setpoint to the two outer zones. This regulation mode provides excellent homogeneity across the entire working area. The control interface allows you to select between cascade regulation or direct furnace regulation (without specimen contact), depending on your test constraints.

Thus, upgrading to a multi-zone configuration improves the stability of thermal cycles and fully complies with the requirements of ISO 204:2023 for creep testing.

We modernise the control interface of your creep testing machine by integrating an HMI (Human-Machine Interface) with a 7-inch, 10-inch, or standard PC touchscreen panel, offering: user-friendly supervision with interactive synoptics, unlimited recipe programming and storage, real-time curve plotting, batch file reading, configurable alarm thresholds, fault logging, data export in .csv format for spreadsheet analysis, and more.

If your control, regulation, or data acquisition chain is obsolete, we can modernise and secure these different functions:

These upgrades ensure more precise, intuitive, and secure control of your thermal equipment.

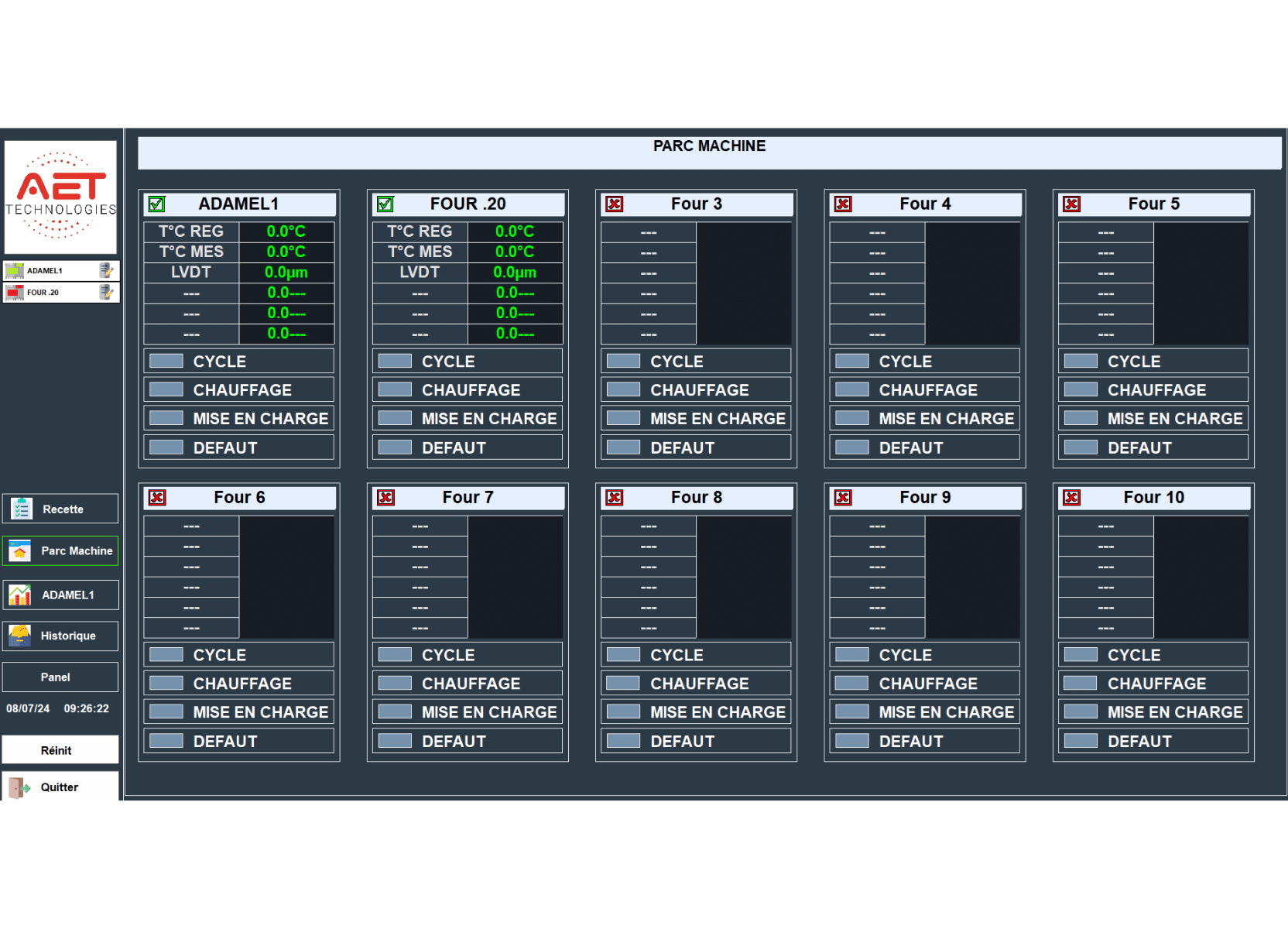

The supervision of your creep testing machines is managed by dedicated software designed to control and monitor up to 20 machines simultaneously from a single PC. This HMI provides real-time control of your equipment, centralised data management, and continuous test monitoring.

The software supports you from recipe configuration through to the analysis of your test campaign data.

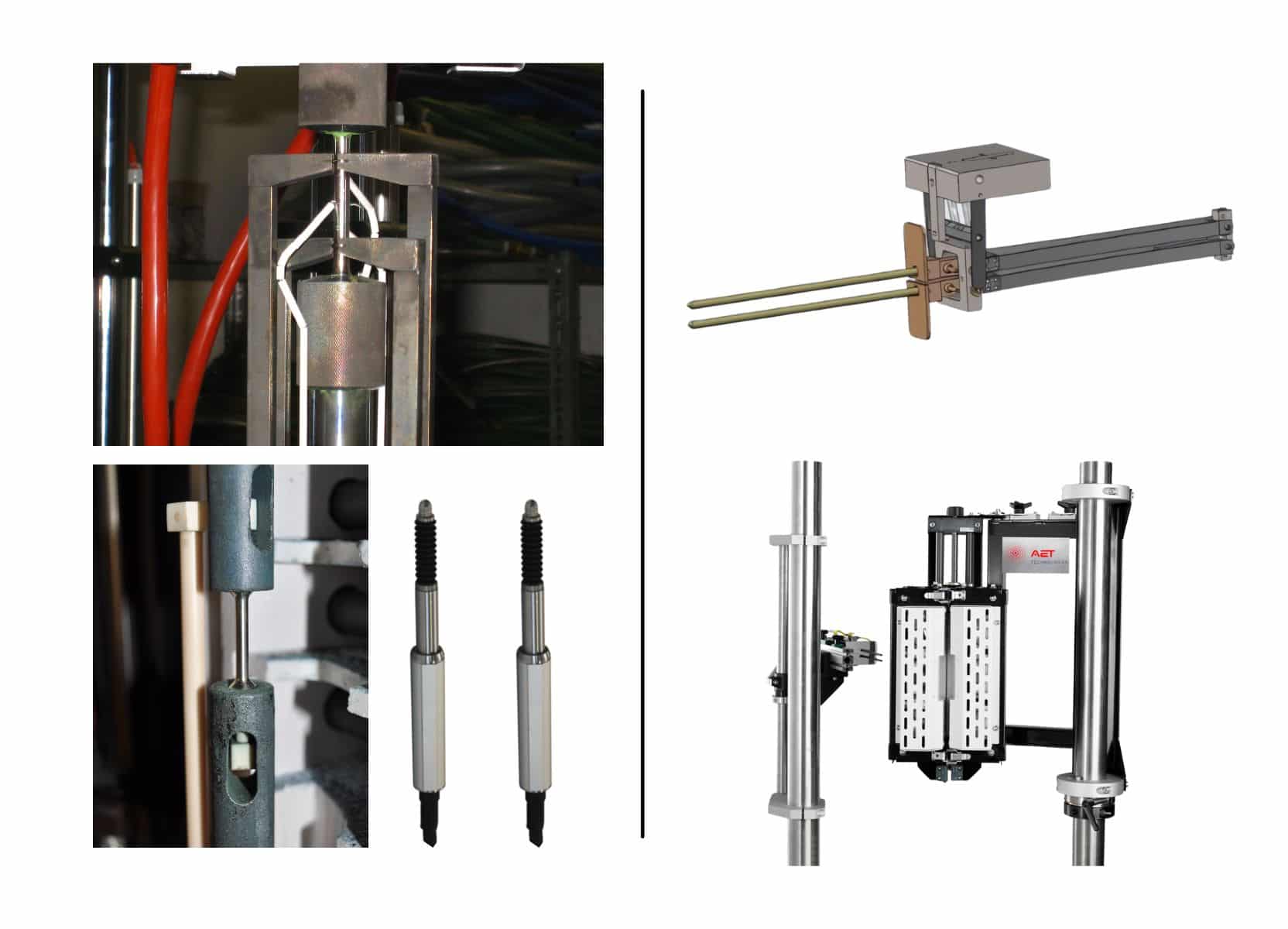

AET Technologies supports you in modernising and optimising your deformation and/or force measurement systems. The upgrade can serve two purposes: replacing obsolete components (sensors, actuators, mechanical or electrical parts, etc.) and/or improving reliability and enhancing the performance of your testing bench.

We offer the integration of LVDT displacement sensors, ensuring precise and continuous deformation monitoring. Depending on your furnace configuration and measurement requirements, other deformation measurement systems can also be added.

We are able to offer our clients an end-to-end approach thanks to our technical skills and the experience of our teams.

A unique and advanced technological solution dedicated to the oxidation phase involved in the manufacture of VCSELs