AET Technologies creep testing machines combine precision, robustness, and thermal control. Designed to accurately reproduce the extreme temperature and stress conditions experienced by materials in service, they are benchmark equipment for long-duration mechanical testing.

Available in nine versions — TCN 10, 20, 30 and 50 kN (minimum capacities of 2, 3 and 5 kN) — for maximum temperatures of 1000 °C, 1300 °C and 1500 °C, they meet the needs of laboratories, research centres and industrial sites involved in material qualification.

Contact us All our solutions

AET Technologies’ TCN machines deliver exceptional lifespan, reliability, and both thermal and mechanical stability. Their four high-rigidity load-column design ensures precise stress maintenance during tests lasting several thousand hours.

With nominal capacities ranging from 20 to 50 kN and a class 0.5 accuracy (ISO 7500-2), they provide progressive, reproducible loading compliant with ISO 204 and ASTM E139 standards.

Independent tri-zone furnaces, available up to 1500 °C, enable precise thermal control, with regulation on the furnace or directly on the specimen for optimal temperature uniformity within the working zone.

The weight-based or motor-driven loading system enables automated, repeatable, and safe loading/unloading cycles.

The motor-controlled loading technology ensures precise and stable control throughout the test while minimising manual handling. An optional backup power system maintains the load in the event of a power outage.

Tests can be conducted in continuous or interrupted creep modes, in compliance with ISO 204:2023, which defines the required gradients and thermal homogeneity.

Automatic specimen alignment ensures test compliance and eliminates any setup bias.

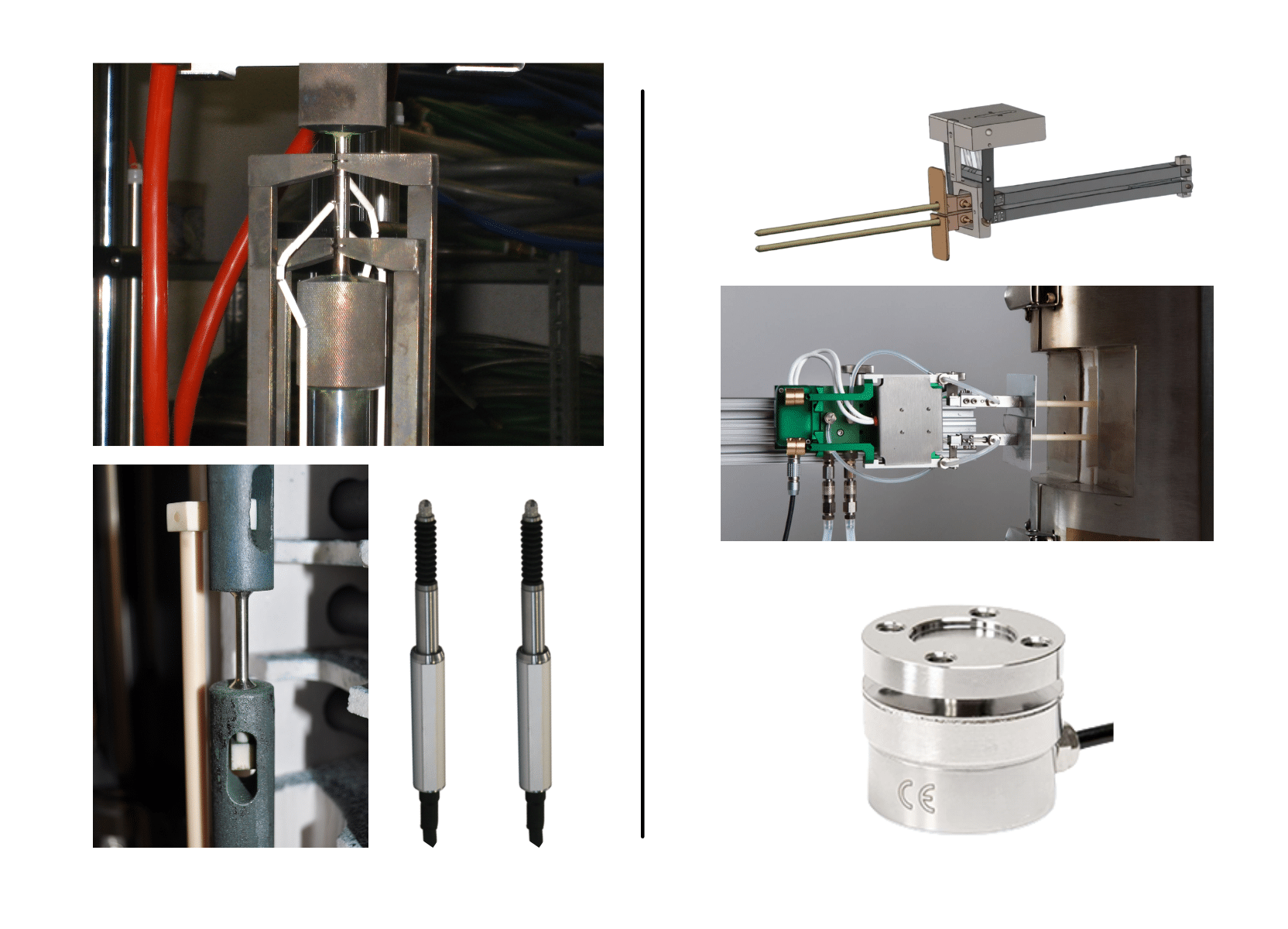

The machines are equipped with a class 0.5 load cell and LVDT extensometers for precise measurement of creep deformations (gauge length Le: 13 to 60 mm, measurement travel: 30 mm, accuracy: ± 1 µm, optional precision up to ± 0.2 µm). Depending on the furnace configuration and measurement requirements, other strain measurement systems can be added.

This instrumentation guarantees consistent, reproducible results directly usable for lifetime and minimum creep rate calculations.

Contact us

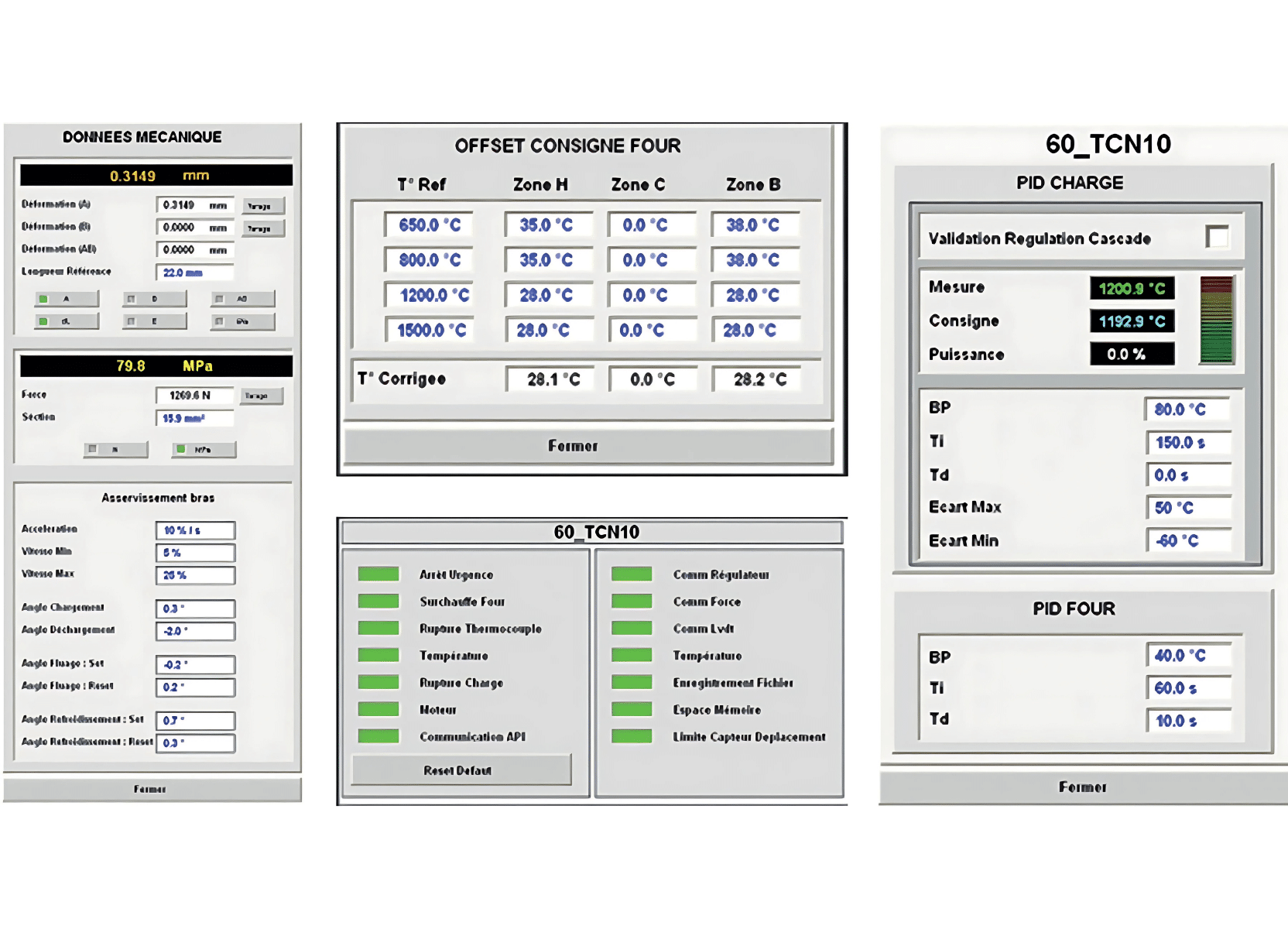

Each machine integrates an embedded TCN digital controller with a colour touchscreen and large memory capacity.

Operation is managed via a touchscreen HMI offering user-friendly supervision with interactive synoptics, unlimited recipe programming and recording, real-time curve plotting, batch file reading, adjustable alarm thresholds, fault logs, and .csv data export for spreadsheet processing.

Data acquisition and recording occur within the internal controller, independently from the connected PC network, ensuring measurement security.

Optionally, creep analysis software allows plotting and calculation of parameters such as rupture time and minimum creep rate, with report generation including curves.

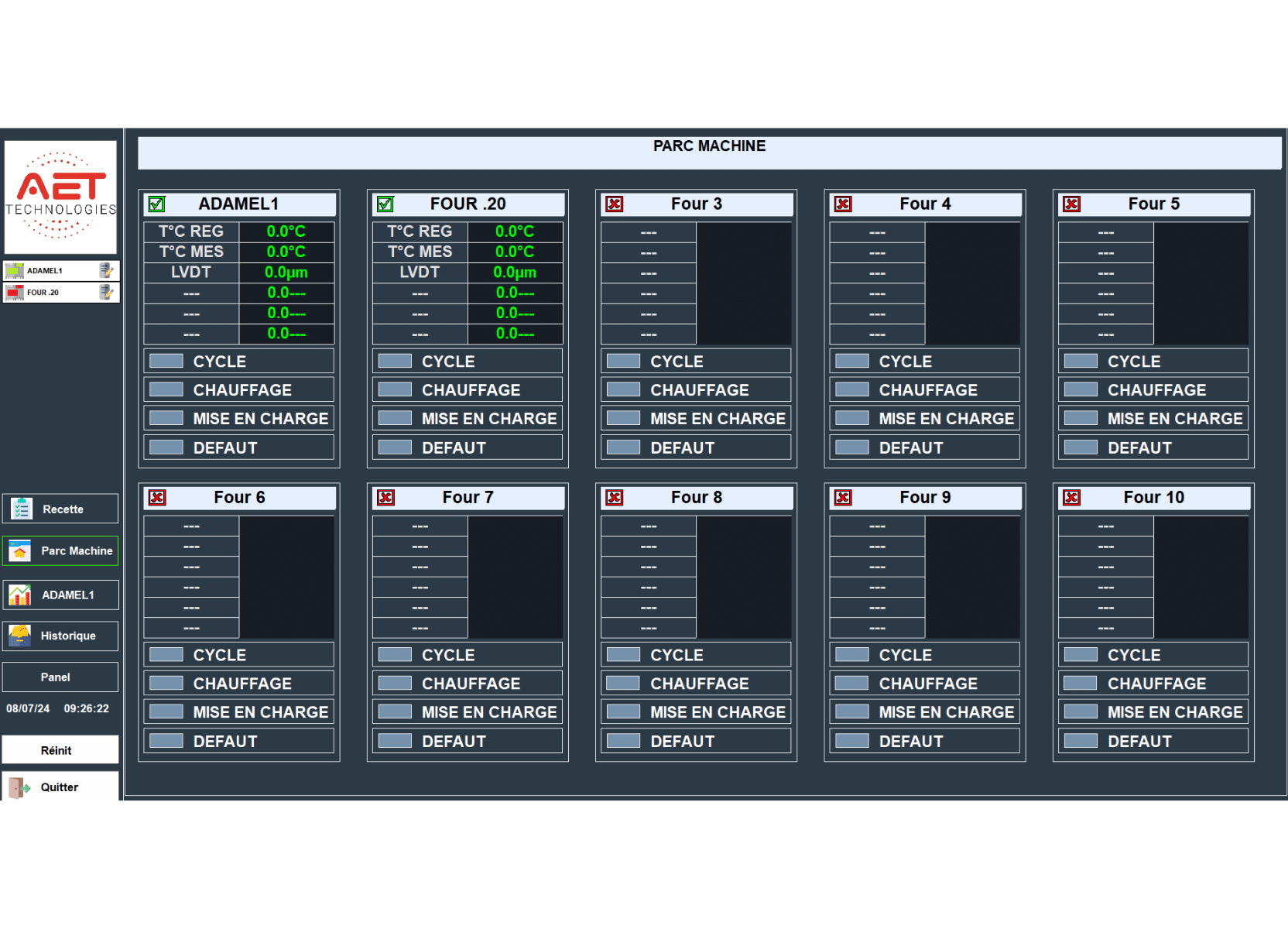

AET’s supervision software enables simultaneous control of up to 20 machines from a single interface.

This HMI provides real-time monitoring of your equipment fleet, data centralisation, and continuous test tracking.

The system architecture streamlines test campaign planning, preventive maintenance, and coordination of multi-equipment setups.

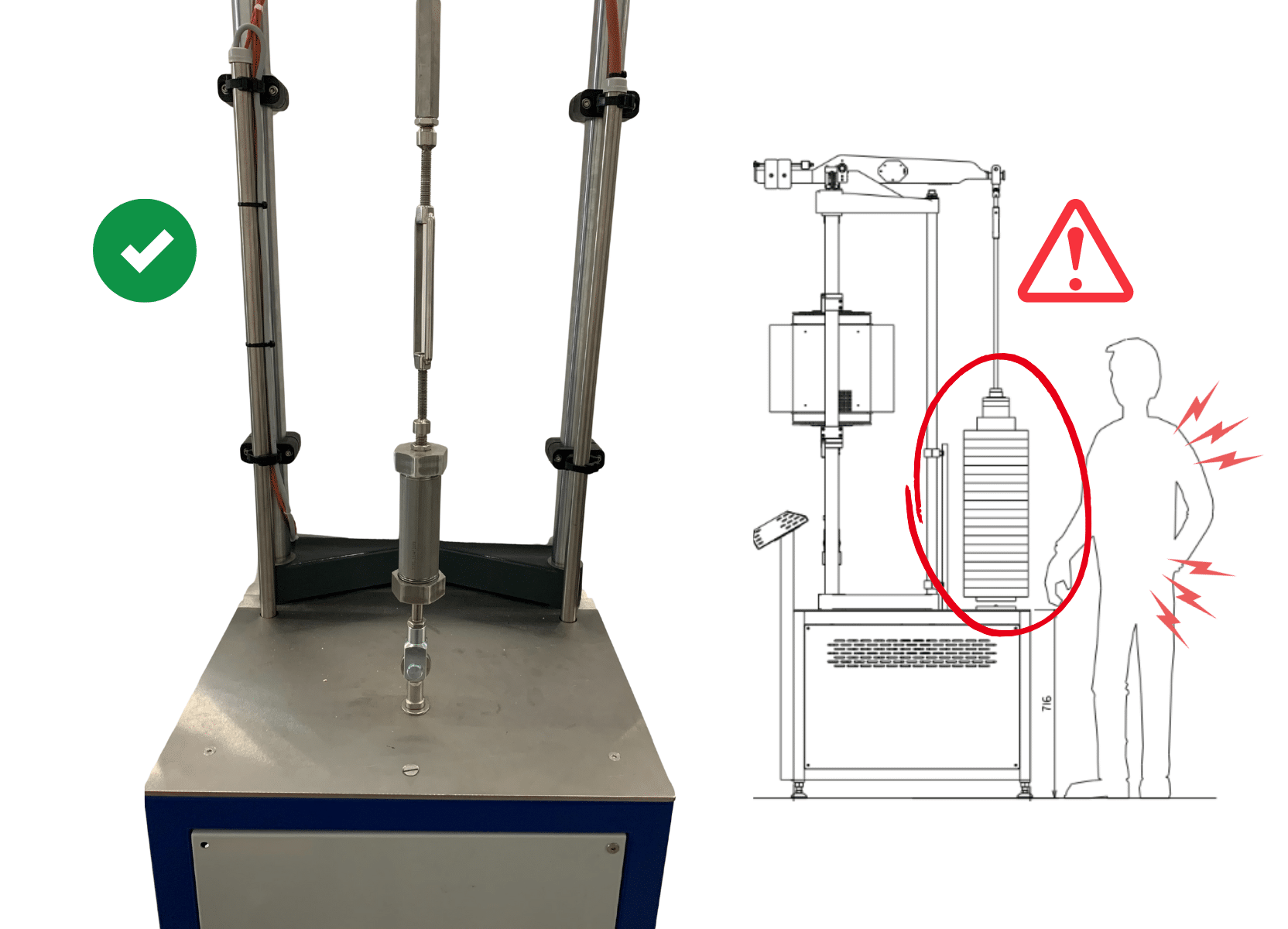

Traditionally, creep testing machines rely on manual loading. Handling weights can cause jerks or uncontrolled loading, contrary to creep testing standards.

To improve test quality, AET Technologies has developed a motor-driven mechanical system to control the loading process. This technology keeps the weights mounted on the machine and allows a programmable load progression (with speed and weight control and recording), ensuring smooth loading/unloading, reproducible tests, and improved compliance with standards.

Most legacy creep testing machines still rely on manual loading, requiring the handling of heavy weights. This repetitive operation, often carried out under demanding conditions, exposes operators to musculoskeletal disorders (MSDs) and increases the risk of handling errors.

To address this, AET Technologies offers an innovative retrofit solution featuring a fully motor-controlled loading system — weight-free, handling-free, and fully programmable. This upgrade expands loading modes through the integration of arithmetic and geometric algorithms, enhancing test quality and precision. Contact us for an equipment diagnostic.

We are able to offer our clients an end-to-end approach thanks to our technical skills and the experience of our teams.

A unique and advanced technological solution dedicated to the oxidation phase involved in the manufacture of VCSELs