AET Technologies designs and manufactures a complete range of creep testing equipment intended for mechanical testing. These creep testing systems, developed in France, are designed to meet the needs of laboratories, research centres and demanding industrial users wishing to analyse the behaviour of materials under stress and temperature.

We provide in particular standard creep testing machines, special creep testing machines, as well as creep furnaces adapted to multiple configurations (opening, non-opening, high temperature). All our equipment complies with CE standards and is manufactured using materials in accordance with current legislation.

In addition, our retrofit solutions provide the possibility to modernise your existing equipment in order to improve its performance, reliability, and compliance with current standards.

Contact us All our solutions

AET Technologies creep testing machines are designed to reproduce with the highest accuracy the extreme conditions to which materials are subjected in service. They apply a constant stress to a specimen for extended periods, sometimes exceeding several thousand hours, while maintaining a stable and homogeneous thermal regulation.

Available in 9 versions — TCN 20/30/50 kN up to 1000 °C, TCN 20/30/50 kN up to 1300 °C, and TCN 20/30/50 kN up to 1500 °C — these systems cover all requirements, from the characterisation of standard alloys to the qualification of superalloys used in aerospace, energy, and nuclear industries. Each machine combines a robust loading system, high-precision multi-zone furnaces, and sensors adapted to the very low strain rates characteristic of creep.

Compliant with international standards (ISO 204, ASTM E139), AET Technologies creep testing machines ensure the reliability, traceability, and reproducibility essential for both scientific research and industry.

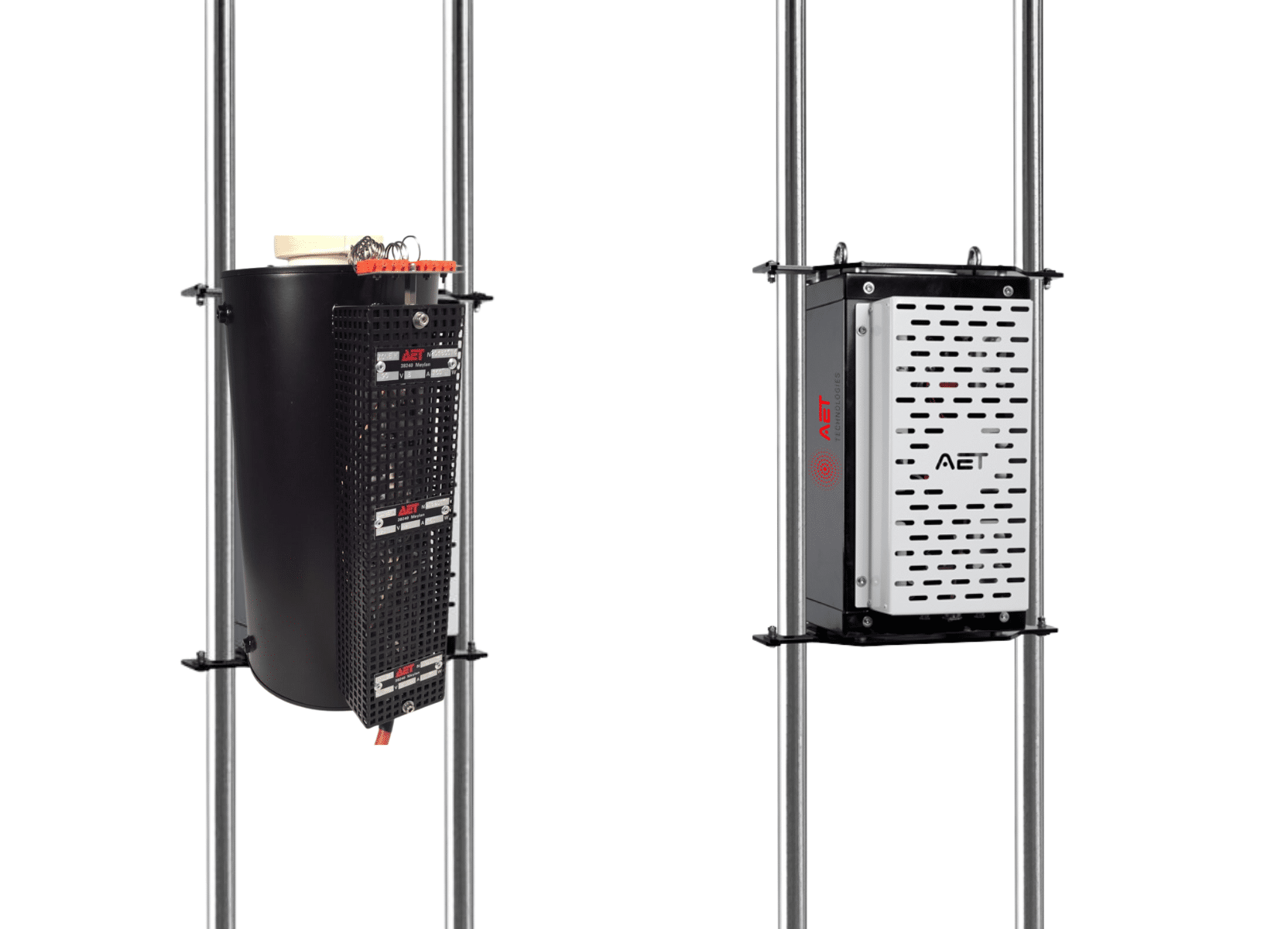

The non-opening creep furnaces designed by AET Technologies provide outstanding thermal homogeneity and stability for long-term testing. Thanks to their compact and perfectly insulated design, they minimise energy losses and ensure precise temperature control, an essential condition for the reliability of creep testing. Depending on requirements, regulation can be performed either directly on the furnace or at the specimen level.

Available in several versions — up to 1000 °C, up to 1300 °C, and up to 1500 °C — these furnaces meet all requirements, from studies on steels and common alloys to advanced research on superalloys at very high temperatures. Elongation measurement is carried out using an LVDT (Linear Variable Differential Transformer) sensor. Their design is particularly well suited for standardised testing (ISO 204, ASTM E139), where accuracy and reproducibility are essential.

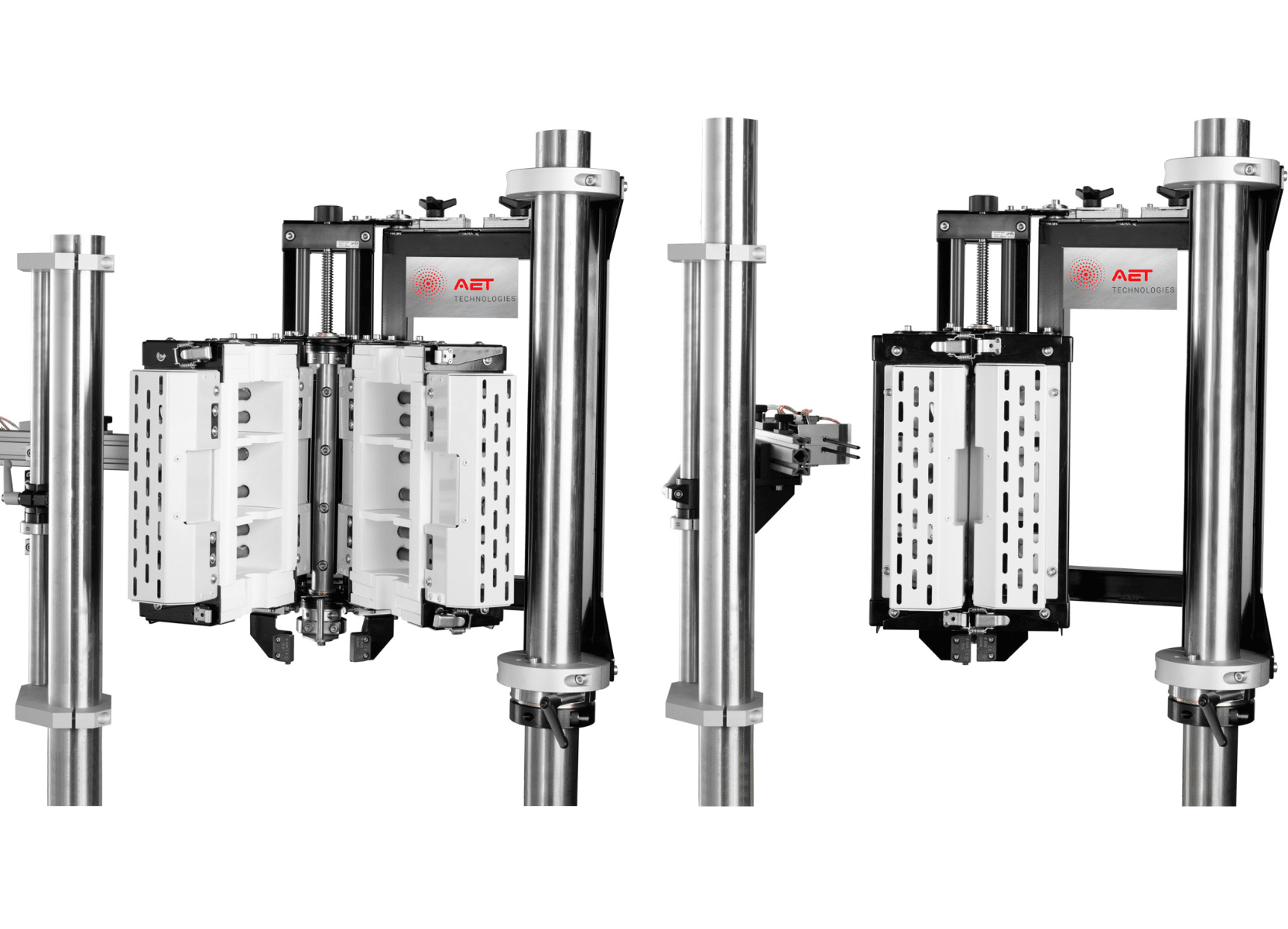

AET Technologies opening creep furnaces combine thermal performance with user-friendly operation. Their front-opening or side-opening design facilitates specimen setup, visual inspection, as well as maintenance and calibration operations, while ensuring a high level of thermal homogeneity. Depending on requirements, regulation can be performed either directly on the furnace or at the specimen level. These models are compatible with axial or transverse mounted contact extensometers.

Available in versions up to 1000 °C, up to 1300 °C, and up to 1500 °C, these furnaces meet the diverse needs of laboratories and industry, whether for characterising conventional metallic materials or qualifying critical alloys for aerospace and energy applications. They provide the expected regulation accuracy for long-term testing while simplifying handling and traceability of experimental campaigns.

At AET Technologies, the design of special creep testing machines demonstrates our ability to push the limits of thermal and mechanical engineering. An example is a creep testing machine capable of reaching 1500 °C in a controlled atmosphere or under vacuum: sealed furnaces, graphite insulation, suitable heating elements, control via thermocouples and optical pyrometer — everything is designed to ensure accuracy and reliability. These tailor-made systems meet the most demanding requirements, whether studying creep in a neutral atmosphere, limiting high-temperature oxidation, or reproducing extreme environments with perfect test traceability. With full expertise in heating technologies, atmosphere control, and regulation, AET provides unique solutions for both fundamental research and strategic industrial applications.

The retrofit solutions developed by AET Technologies extend the service life of your creep testing equipment, regardless of the original brand, while integrating the latest technological advances. Whether increasing the operating temperature, upgrading from single-zone to multi-zone regulation, modernising control systems, or integrating new-generation measuring devices, each upgrade enhances the precision, homogeneity, and compliance of your tests. Our services cover all requirements, from thermal upgrades to centralised supervision of multiple machines, in order to meet the growing demands for performance and international standards (ISO 204, ASTM E139, ASTM E292, ASTM E2714).

We are able to offer our clients an end-to-end approach thanks to our technical skills and the experience of our teams.

A unique and advanced technological solution dedicated to the oxidation phase involved in the manufacture of VCSELs