This universal tubular furnace stands out for the unmatched quality of the results achieved. It is specifically designed for demanding research laboratories seeking a high-performance, reliable solution compatible with long-duration testing and heat treatment processes.

The quality and robustness of its construction ensure long service life, low maintenance requirements, and ease of use. This furnace is available in several versions: 1300°C, 1500°C, and 1700°C.

| Caractéristiques (Fr) | Specifications (Eng) | |

|---|---|---|

|

1700°C Temp max / Thermocouple Type B 1600°C Temp max / |

1700°C Max Temp / Type B Thermocouple |

|

|

1 ou 3 zones de chauffe |

1 or 3 heating zones |

|

|

50-85mm de diamètre utile interne |

50-85mm internal useful diameter |

|

|

Options gaz : jusqu’à 3 lignes de gaz neutres (air, azote, argon, hélium) |

Gas options: up to 3 neutral gas lines (air, nitrogen, argon, helium) |

|

|

Homogénéité thermique <±5°C |

Thermal homogeneity <±5°C |

|

|

Monozone ou trizones (option TC d’instrumentation étanche) |

Thermocouple options for best instrumentation furnace and load |

|

|

Ecrans thermiques et support de charge adaptés aux besoins process |

Thermal shields and load-bearing supports tailored to process requirements. |

|

|

Interface IHM : écran tactile couleur de 7 pouces (coffret electrique de table) |

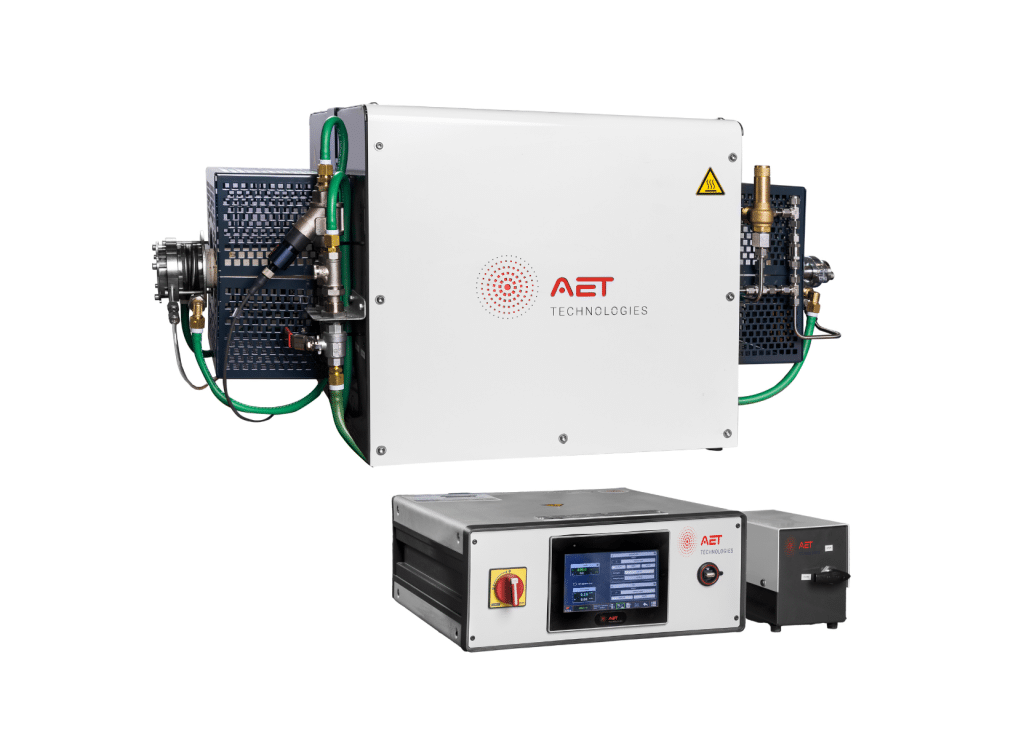

HMI interface: 7-inch color touchscreen (desktop electrical control cabinet). |

|

|

USB en arrière pour fichier CSV, connexion Ethernet |

USB panel for CSV file, Ethernet connection |

|

|

Puissance max : 4kW en monophasé, 8kW en triphasé |

Maximum power: 4 kW single-phase, 8 kW three-phase |

|

|

Options |

||

|

Options vide : primaire, secondaire |

Vaccum options: primary, secondary vacuum |

|

|

Châssis horizontal disponible en option |

Horizontal chassis available as an option |

We are able to offer our clients an end-to-end approach thanks to our technical skills and the experience of our teams.

A unique and advanced technological solution dedicated to the oxidation phase involved in the manufacture of VCSELs