All our equipment is CE-compliant and manufactured using materials that meet current regulations.

| Caractéristiques (Fr) | Specifications (Eng) | |||

|---|---|---|---|---|

|

Type de four Type of furnace |

|

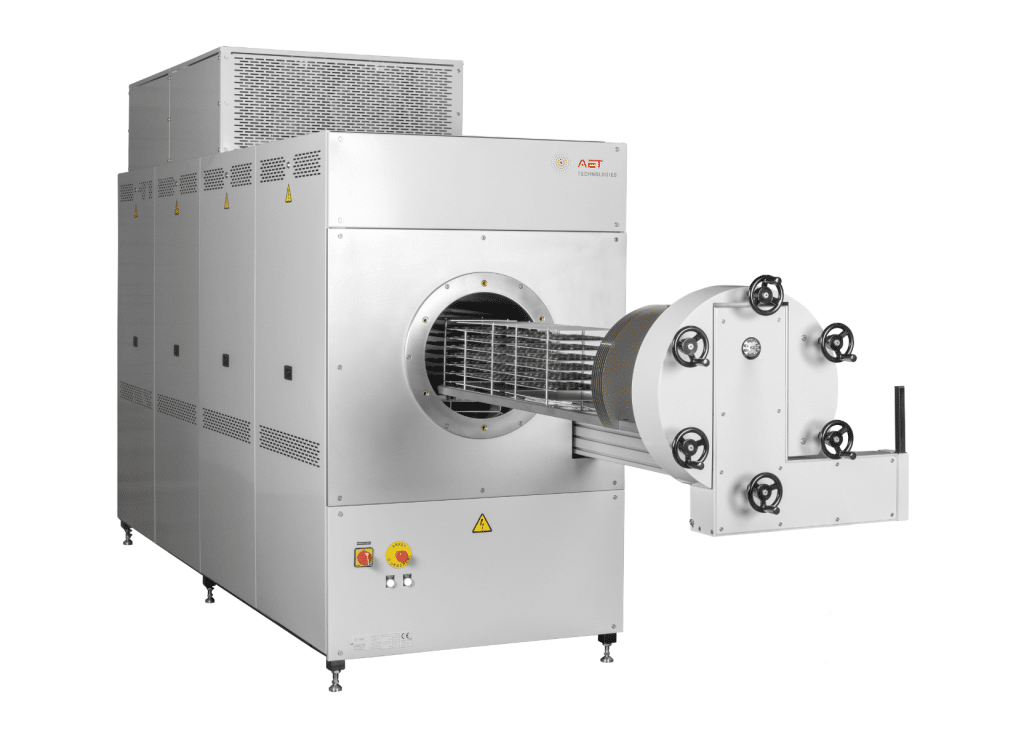

Sealed furnace – Clean atmosphere |

||

|

Compatibilité Salle blanche Clean Room Compatibility |

Oui |

Yes |

||

|

Atmosphère de travail Process |

Air Atmosphère contrôlé (oxydant, neutre, hydrogéné, autres selon besoin) vide primaire et secondaire *selon température et chambre process

|

Air Controlled atmosphere (oxidizing, neutral, hydrogenated, further gas as needed) Primary and secondary vacuum

|

||

|

Température Maximale Maximum temperature |

|

|

||

|

Diamètre disponible Available diameter |

Tube métal = Ø420mm=800°C |

Metal tube = Ø420 mm = 800°C |

||

|

Homogénéité Thermique Thermal homogeneity |

<+/- 5°C |

<+/- 5°C

|

||

|

Longueur de tube laboratoire en mm Laboratory tube sizes in mm |

2500 |

2500 |

||

|

Diamètre du tube laboratoire en mm |

420 |

420 |

||

|

Dimensionnement volume utile (L x l x h en mm)

Usable Volume |

1100 mm x 240 mm x 240 mm |

1100 mm x 240 mm x 240 mm |

||

|

Tube laboratoire* Laboratory tube*

*sous réserve compatibilité matériaux, gaz, température *subject to material, gas and temperature compatibility |

métallique, quartz |

|

||

|

Pression Pressure |

pression atmosphérique régulation de pression < à la pression atmosphérique vide |

atmospheric pressure pressure regulation < atmospheric pressure vacuum |

||

|

Vide Vaccum |

< 6 × 10⁻⁷ |

< 6 × 10⁻⁷ |

||

|

Taux de fuite Leakage rate |

1 10-8 mbar.l/s |

1 10-8 mbar.l/s |

||

|

Application Application |

Dégazage, scellement verre/métal, polymérisation, pyrolyse, recuit… |

Degassing, glass/metal sealing, polymerization,rapid thermal process… |

||

|

Chargement manuel Manual loading |

Porte sur glissière |

Sliding door |

||

|

Ergonomie du poste de chargement Loading station ergonomics |

Excellente (à l’extérieur de la chambre process) |

Excellent (outside the process chamber) |

||

|

Hauteur du chargement à l’extérieur du four |

1100 mm |

1100 mm |

||

|

Autres options |

|

Dry or wet gas: dew point control |

We are able to offer our clients an end-to-end approach thanks to our technical skills and the experience of our teams.

A unique and advanced technological solution dedicated to the oxidation phase involved in the manufacture of VCSELs